Home > Products

OUR PRODUCTS

- The main features of our cylinders -

- They are “TYPE 4”: this means that are made out of composite material, carbon fiber and epoxy resin, and underneath an ultralight liner made of PET (Polyethylene terephthalate)

- Built according to EN12245 and ISO11119-3 standards

- NON-LIMITED LIFE

- For Firefighting, Diving, Industrial and Hydrogen applications

- They are certified according to European Pressure Equipment Directive PED 2014/68/EU (CE), European Pressure Directive T- PED 2010/35/EU (π); US - D.O.T. approved

LIGHTNESS

CTS cylinders are 4 times lighter than the corresponding steel cylinders and 30% lighter than composite cylinders with an aluminium inner core

NON LIMITED LIFE

In accordance with EN12245 or ISO 11119-3, CTS cylinders, certified by Bureau Veritas, withstand more than 12,000 charge cycles at the test pressure, which is one and a half times the working pressure

Exceptional RESISTANCE

Among the tests to be carried out according to the standards are:

– Burst test (the burst test must be more than 3 times the working pressure)

– Cyclic test (in order for the cylinder to be defined as having unlimited life, it must pass 12,000 cycles at the test pressure, i.e. at 1.5 times working pressure)

– Salt water immersion test (one cylinder must pass the burst test and another the cyclic test after being immersed 90 days in water and salt).

– Fire test (cylinder, loaded with air at working pressure, immersed in flames must not burst within 2 minutes).

– Flaw test (two cylinders are notched according to dimensions prescribed by the standard, then one is subjected to the burst test and must exceed 2 times working pressure, while the other is subjected to a cyclic test and must exceed 5,000 cycles at working pressure).

– Hydrostatic test, test performed on all cylinders (each cylinder must be pressurised with water to 1.5 times working pressure and held for at least 30 seconds in that condition)

– Drop test (two cylinders are dropped from a height of 120 cm 8 times, in different positions. One is then subjected to the burst test, while the other is subjected to the cyclic test.

SAFETY guaranteed

CTS goes beyond the requirements of the standard and, to ensure the safety and reliability of its cylinders, regularly performs a series of additional tests:

– Cyclic air fast-fill test, a test performed during the design phase and then on a sample basis on manufactured cylinders (fast filling from 0 bar to 330 bar in less than 60 seconds with air).

– Burst test after cyclic test, test carried out in the design phase and then by sampling on produced cylinders (cylinder subjected to cyclic test and after approx. 12,500 cycles is subjected to bursting, criteria as per standard).

– Low-pressure leak test, test performed on all cylinders (cylinder is loaded with air at 5 bar pressure and then its correct tightness is verified by immersion in soapy water).

– High-pressure leak test, test performed on all cylinders (cylinder is loaded with air at working pressure and then its correct tightness is verified by immersion in soapy water).

BARRIER EFFECT

CTS cylinders meet the requirements of EN 12245 and ISO 11119-3 by a wide margin, and this is due to the unique design and the special PET ‘blend’ of the inner liner

High CORROSION Resistance

The classic problem of oxidation of the inner core, with the very dangerous risk of valve clogging, in CTS cylinders is averted by the use of PET instead of traditional metals.

Easy to CLEAN and SANITISE

A simple cloth soaked in alcohol or non-toxic detergent is all that is needed to easily clean the canisters; hygienisation is also simplified thanks to the screw nozzles made of special anodised aluminium alloys.

Easy MAINTENANCE

Design features such as the carbon fibre and resin composite structure, the PET core, the special caps and sheats, and the interchangeable nozzle, greatly simplify any maintenance work

CUSTOMIZATION

CTS carbon fibre cylinders are adaptable to satisfy the most different needs and requirements for the use of compressed gases. Please present us your requests and we will be glad to propose a customised solution

what does type 4 mean?

Type 1

All-metal cylinder

Type 2

Metal cylinder, wrapped with composite material on the cylindrical part

Type 3

Metal cylinder, entirely wrapped with composite material

Type 4

Cylinder with non-structural liner, fully composite-wrapped

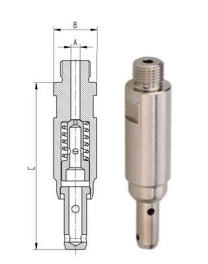

Wide range of valves from which you can choose

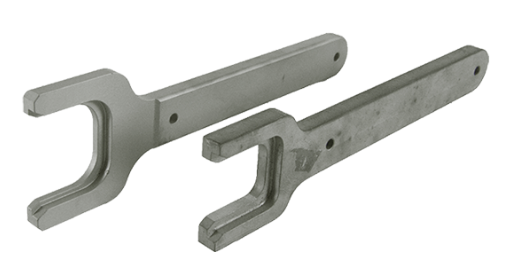

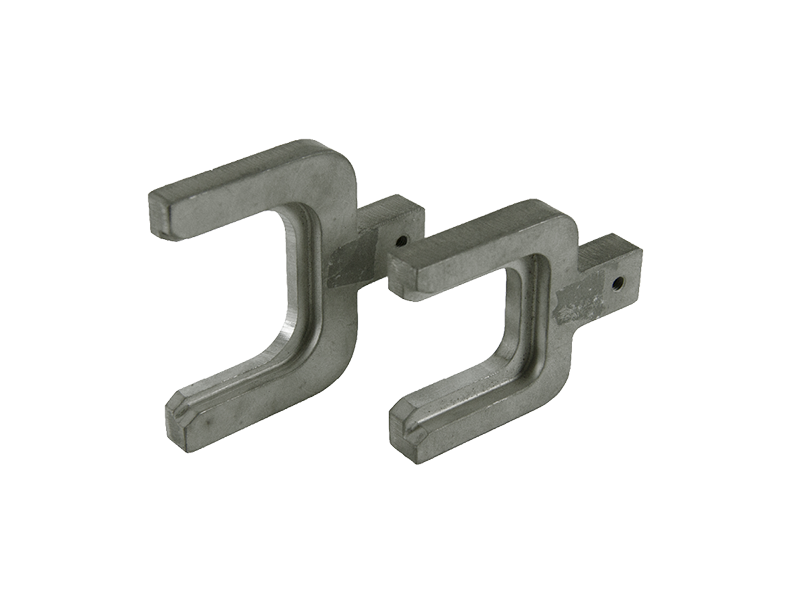

Maintenance and repair has never been easier

CTS’s composite cylinder are made with a non-structural PET liner, wrapped with a composite material made of carbon fibres and epoxy resin, which confers the structural and mechanical properties. The plastic liner has the only function to contain the gas. The cylinder comes with rubber protective caps (upper and bottom) which have the purpose of cushioning the impacts. It can also come with protective sleeves, which are intended to protect the composite surface and the label and also work as a flame retardant.

Inner nozzle

Internal PET liner

Composite shell

Upper cap

Label

Optional protective finishings

Bottom cap